what can i spray on car decals to keep them fresh

I recollect yous'll hold with me when I say that it'due south super disappointing when y'all go to all the problem to make handmade stickers, and your ink runs when it gets a little wet. Or the newspaper starts to peel, or the images fade with exposure. Knowing the best ways to protect your stickers means you don't take to worry virtually how your stickers will hold up to different situations or applications. You can apply waterproof stickers/decals in more places (like water bottles), and as a bonus, the ink won't fade equally quickly either. I loved the idea of making sealed stickers, but I thought you needed expensive paper, or you needed to have a fancy machine. But when I looked into it, I found there were actually 3 methods to waterproof stickers that I really liked considering they either saved me time, saved me coin, or were simple to apply. In this post, I'll let yous know what the 3 methods to protect your stickers are and give y'all the Pros and Cons for each so you can decide which method is best for you.

Table of Contents

Why Seal and Protect Your Stickers

Protecting your stickers by sealing makes them waterproof, and longer-lasting (as they frequently become scratch-resistant,fade-resistant, and the ink won't run). Absurd, right?

You can confidently use them as custom car window decals, phone stickers, or water bottle stickers. Yous can even put waterproof stickers that are sealed in the dishwasher.

The Deviation Between Waterproof and H2o-Resistant Sticker Paper

If you lot await for legit sticker papers, y'all'll see that the best you lot can get is h2oresistant. That means that if exposed to small amounts of h2o, the paper itself tin repel information technology.

Waterproof is a stronger claim and ways that you can practise more than than briefly betrayal the sticker to water. It's kind of like the difference between a quick sprinkling and a dip in a pond pool.

It'due south best to get-go with a waterproof material as your base. Not merely 1 that is water resistant.

Use Printable Vinyl and Add together a Laminate for Super Resilient (and Weatherproof Stickers)

Sticker newspaper is made of paper usually, which is a highly absorbent surface. And because the ink will often run when wet, you lot'll often get a soggy, h2o-logged, and unreadable sticker when wet.

If you beginning with printable vinyl, your sticker surface won't absorb water but repel it. This means the sticker itself will not break downwardly (like a paper product would) when exposed to water.

Many companies say that their printable vinyl is completely waterproof and it doesn't need any kind of sealer as long as yous utilize uv inks.

Still, when I tested printable vinyl with multiple washes, I found that even with printable vinyl, the ink can run.

And then for truly waterproof stickersoffset with printable vinyl- it's your all-time option for super durable and long-lasting stickers.

This gives yous a swell quality production to sell.

Adding an additional protective layer (like a laminate) to the top of your custom stickers will protect the ink and brand the surface more scratch-resistant (depending on the method you choose). This durable materialwill also brand your print stay more vibrant, provide UV protection, and make it dishwasher safe!

Doing outdoor applications like custom labels for outdoor equipment like army camp gear? Then using i of these methods is admittedly necessary.

Waterproof vinyl stickers are a great way to brand bumper stickers, laptop stickers, school supplies boxes, food containers that are long-lasting. With this philharmonic fifty-fifty a water bottle sticker or hydro flask stickers can be completely protected and waterproof.

Get Gratuitous Stickers!

Subscribe today and go the password to my Freebie Library and grab the Watercolor Daisy Sticker Designs for free.

You'll go 3 paw-drawn sticker designs in yellow, greenish, and pink. In the photo I added text to the pink bloom and flattened it before I impress and then cut to make jar labels- and you can too!

The Three Best Methods to Protect and Waterproof Your Stickers

These are my 3 favorite methods to waterproof stickers. And they're pretty popular means of sealing and protecting your stickers.

There are pros and cons to each, which I'll explain below and then yous take the important information you need to cull the method that's all-time for you and your modest business organization.

Method #ane

The Self-Agglutinative Laminating Method

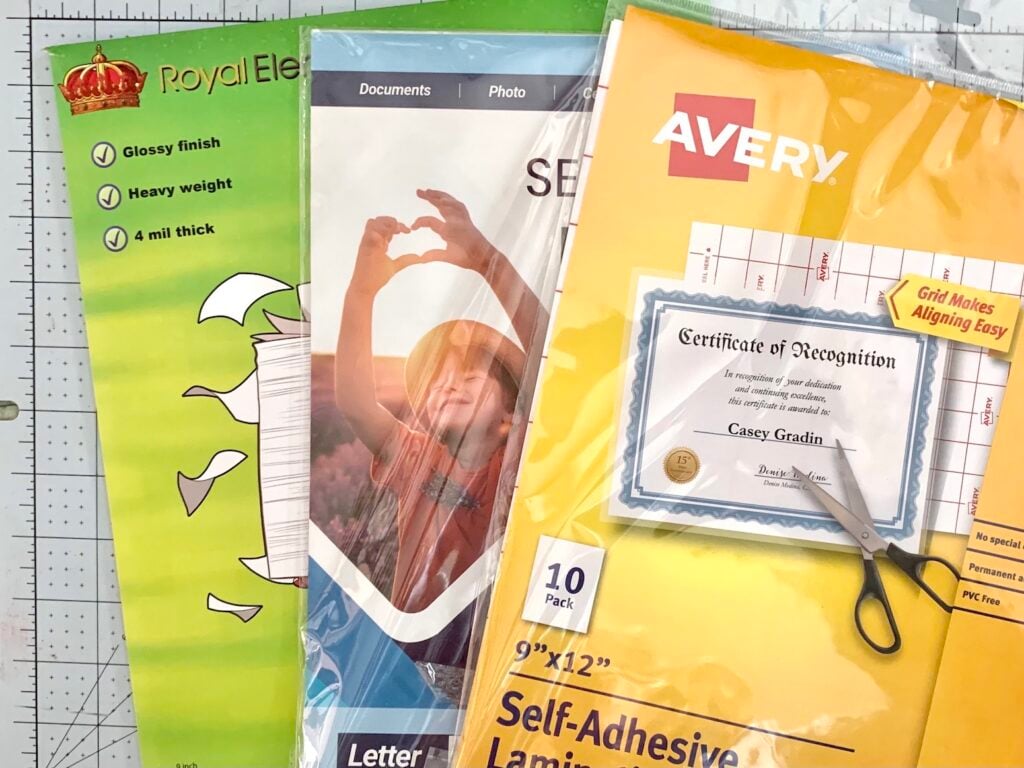

This is a articulate plastic moving-picture show that is agglutinative on 1 side and will stick to your sticker'south surface thereby sealing it. You can sub clear sticker paper, but laminating sheets frequently are larger and so they encase the whole newspaper giving you a margin for mistakes in your application.

I have a footstep-past-stride tutorial for applying self-adhesive laminate in my mail, How to Waterproof Your Stickers [Laminate 101]. I as well exam three different brands of the laminate and have recommendations so you can find the one that'south right for your custom waterproof labels or clear stickers.

- - Application doesn't require whatever tools other than old credit card + gets easier with practice

- - You can notice different thicknesses (from barely in that location to thickness of a transparency)

- - Because these are meant as lamination they are bigger than needed which makes awarding less stressful

- - Tin be purchased at Office Supply Store or Online

- - No heat, no olfactory property, and no power source needed

- -It's piece of cake to get bubbles or folds that are difficult to get out

- - Information technology tin can be expensive

- - Some brands do not come up clear merely frosted (even if they say clear)

- - Using a scraper to smooth helps with bubbles but can scratch the surface, so be conscientious

- - The edges of the laminate can seem sharp w/ some brands

Tips- Make certain your work surface is clean so at that place is no lint on your stickers earlier y'all laminate. Marshal everything earlier you lot commencement. Go slowly and smooth the surface from heart out to edges.

Method #ii

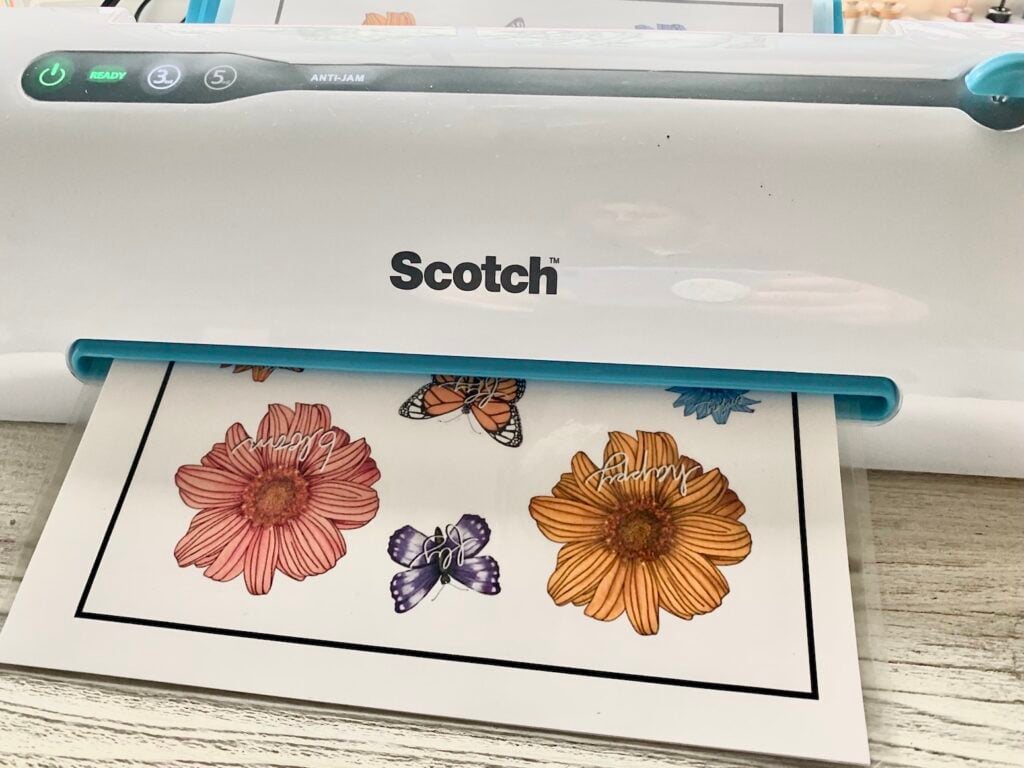

Thermal Laminating Car

I put off getting a laminating machine for a really long time and now that I take one, I'thousand super glad I got it. To use it, you MUST look until the Ready light is on but so you lot just put two sheets of printed stickers back-to-back and insert them into a thermal laminating pouch. Once it's gone through the auto, you trim off the sides, and voila! Two sheets of laminated stickers in less than a minute, making this a bully choice if you lot take to do a lot of stickers at in one case.

To make this method completely waterproof (for things similar water bottles) be sure to utilise printable vinyl, non sticker paper.

I have a tutorial on how to use a laminating machine to protect your stickers in my post, How to Heat Laminate Your Stickers and Labels. In this mail, I besides have my production recommendations.

- - Super Elementary Awarding that'due south Hard to Mess Up

- - Saves time (yous'll laminate two sticker sheets at a time)

- - Articulate consequent and durable surface

- - Tin purchase laminating pouches in 3 mil or 5 mil

- - Pouches come in different sizes

- - Easy to find generic versions of both laminating motorcar and the pouches

- -You need to buy a laminating machine

- -Requires power source

- -Yous'll need space to store the machine (9" -xiii")

- -May take 1-9 minutes to warm upward (depends on automobile)

- -Tin get wavy vertical lines that prove at an angle

- -You may need to printing flat with stack of books

- -It'south SUPER IMPERATIVE you let the machine warm-upwards or your bond won't be secure.

Tips- Once more, make sure your surface is clean before you laminate as it is a permanent application. Wait until the machine is ready to apply before laminating, or you'll go inconsistent areas that appear wavy. And I feel like it's worth it to become a machine with machine shut-off and ii rollers.

If you don't need the auto close-off feature the Amazon brand laminator is a sweet deal. Bank check the dollar store for supplies every bit some take constitute even name-make pouches there!

Method #three

The Aerosol Spray Sealant Method

Spray sealers coat stickers with a shellac-similar polyacrylic surface. If used correctly, they can add an almostinvisible protectant layer over your sticker designs. It can come in glossy or matte, and there are several tried-and-true brands similar Krylon, Mod Podge, and Minwax.

Be sure to expect 24 hours later on you print for the ink to dry out before y'all apply a spray sealant, and make sure yous follow the manufacturer'southward directions for use and rubber precautions.

- - Barely there then it doesn't add together unwanted bulk to your stickers

- - You can do multiple sheets at the same fourth dimension

- - Comes in sleeky/matte, UV protectant, low VOC etc.

- - It can exist purchased at craft stores, hardware stores, or online

- - Inexpensive

- - Like shooting fish in a barrel to find generic versions of both laminating automobile and the pouches

- - Straight up-> yous Need to follow safety precautions (which may include purchasing personal safety equipment)

- - Needs multiple coats and you may need to wait ten-xxx minutes betwixt coats

- - Your coverage must exist total and evenly applied, you'll need to test to exist sure it's working

- - Must be 18+ in some states to purchase

- - Because of VOC fumes you lot must have proper ventilation

- - Temperatures need to be optimal and so y'all may not exist able to spray outside at certain times of the twelvemonth

Tips- I can't stress information technology enough, use safety precautions . Considering they are aerosols, spray sealants can be chancy to your wellness if not used correctly. I identify a big cardboard box out in my one thousand and spray several at once, then set a timer to repeat as many times as needed.

Best Options to Protect and Waterproof Stickers by Projection

All-time Pick if Y'all Want Barely There Results

Spray sealer wins this ane considering you lot can hardly tell it's there, although Avery's Self-Agglutinative Laminating Sheets are super thin and don't add much majority or weight to the sticker.

Best Option for Quick Application: Self-Adhesive Laminating Sheets

There is no prep fourth dimension for the cocky-adhesive sheets, you just line everything up, peel back the height like a hinge, then pull off the backing. You do take to smoothen out the sheet with a carte, but this goes chop-chop once you lot take the hang of information technology.

Best Pick for Like shooting fish in a barrel Awarding of Multiple Sheets: Thermal Laminator

It's so easy to feed sheet after sail through the car and your laminating two sticker sheets dorsum-to-back so information technology goes twice as fast. Once again, it'due south SUPER IMPERATIVE you permit the machine warm-up or your bond won't exist secure.

Best Selection for the Budget-Minded: Spray Sealer

A tin of spray sealer goes a long way and is cheap to brainstorm with, but use a craft store coupon and it's a total steal.

All-time Option for Outdoor Use: Printable Vinyl with a UV Laminating Film to Waterproof Stickers

If you'd similar to make a decal for something that will exist outdoors in the elements then yous want to think farthermost wear and weatherproof, non just waterproof. So use UV-resistant inks, a waterproof printable vinyl base (permanent adhesive), and Oracal UV Laminating Motion picture.

All-time Option for Indoor Use: Self-Agglutinative Sheets or Thermal Laminator

It's more than virtually what you want to avoid- fumes in the firm that a spray sealant would cause. And so either of the other ii methods works better for indoor employ.

All-time Option for Waterproof Car Decals

Start with printable vinyl and if y'all tin, use UV-protectant inks so that you minimize fading. Utilise a self-adhesive laminating sheet (with UV protection) or a thermal laminator and then that you know with certainty that you have absolute coverage over your entire sticker.

Best Option for Water Bottles that are Dishwasher Safe

Printable Vinyl with a Self-Adhesive Laminate. Brand certain you apply a brand of laminate that isn't too thick and so that y'all can curve it around the bottle and become a practiced seal. Avery Self-Adhesive Laminating Sheets are good for this because they are thinner and more than pliable.

Just a note but Majestic Elements claims that their printable vinyl is dishwasher safe without any sealer. Something to exam I think!

Best Selection for Clear Stickers / Labels

If y'all are making custom product labels to go on a candle or glass jar then using a barely-there pick like the Avery Self-Adhesive Labels is your best choice. You too want to use clear sticker newspaper or printable vinyl as your base. Be aware that most types of clear printable vinyl have a frosted end, not completely clear.

My Personal Favorite to Protect and Waterproof Stickers:

Cocky-Adhesive Sheets

To make custom waterproof stickers information technology really was close between my top two favorites, but I think I like the self-agglutinative sheets a lilliputian more. I appreciate how they come up in different thicknesses and materials. Testing three different brands, Avery, Royal, and Violetta, I institute that I preferred the Royal because it was a medium-weight, and it gave me a glossy stickerthen clear that information technology makes my stickers look beautifully saturated and luminous. The cheapest, Avery is also a skillful selection. The Violetta feels similar a transparency sail and the edges seemed a little sharp. I didn't dear that.

My second favorite method of waterproofing is Thermal Laminating. It's seriously SO fun to apply. Just, it sometimes had wavy lines where information technology didn't rut properly, and if I didn't let it warm up the total vii-9 minutes, then the laminate didn't fully bond to the sticker paper surface. It'due south likewise an extra toll that not anybody volition exist okay with spending. I know it took me a long time earlier I purchased ane- I practise wish I'd got one ages agone though!

Beloved Stickers?

I hope you enjoyed this post on how to create loftier quality stickers and water-resistant labels. At present yous can create your own custom stickers the exact size that you desire to get on your car windows, your notebooks, or even your laptop!

And if you've found other ways to protect or waterproof your stickers I'd love to know! It's always awesome to discover new ways to do things. ❤️

Source: https://wellcraftedstudio.com/protect-waterproof-stickers/

0 Response to "what can i spray on car decals to keep them fresh"

Post a Comment